Listen, design and execute.

Dream it.

It all begins with an idea. Maybe you have a creative thought to share with the world. The way you tell your story can make all the difference. We translate that story and make it travel through fabric. With Takshima your idea comes to live, becomes tangible and therefore endorsable.

Build it.

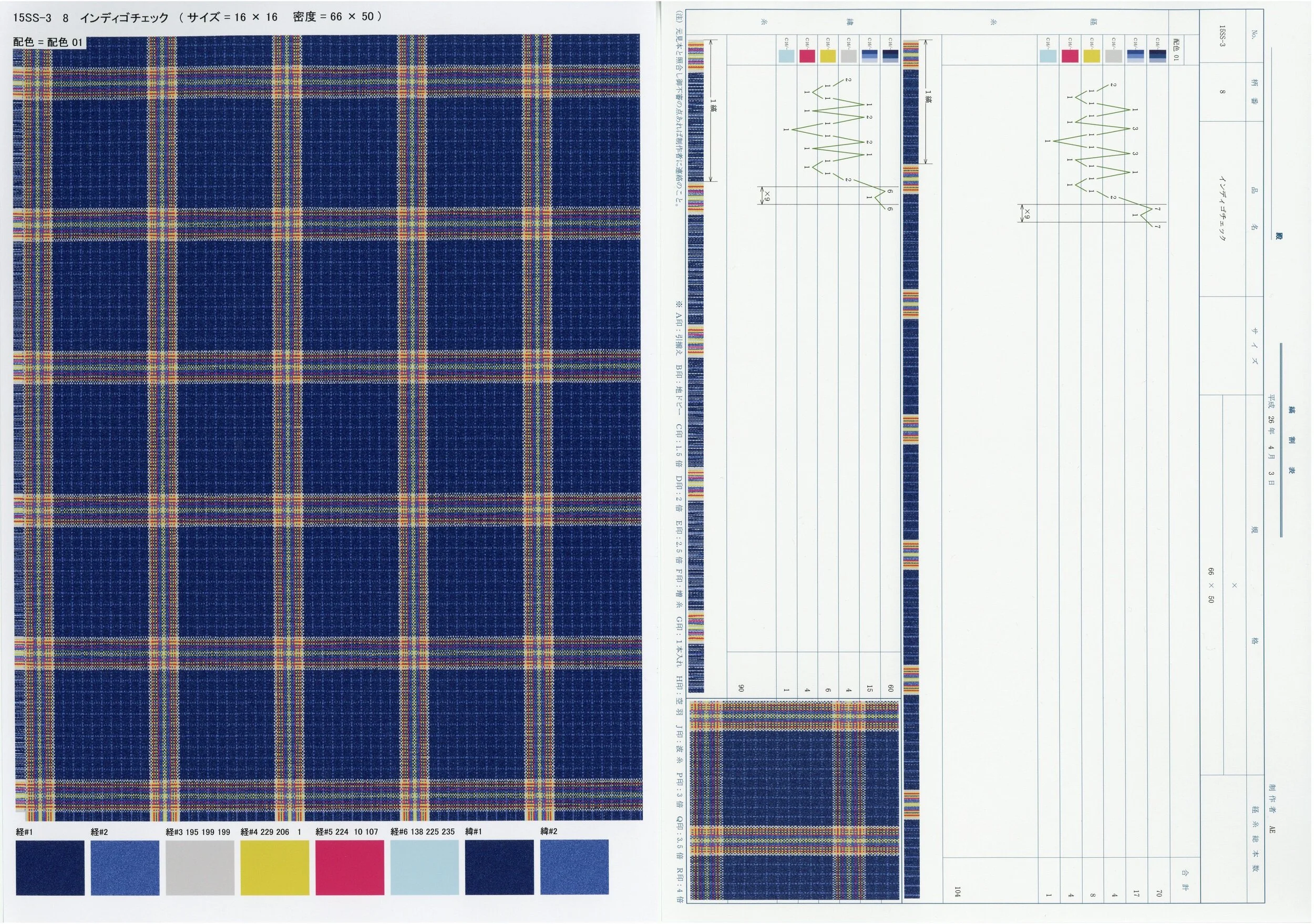

Our team in Japan engineers the pattern design digitally by a special enhanced computer program. They calculate the yarn count and color scheme that make up the lay out of the pattern design. An intricate and arithmetic process that requires precise understanding and talented skills.

Grow it.

The pattern designs are translated into a unique cryptographic code. Weaving machines in the factory are then fed with these instructive ciphers for the shuttles to follow the pattern accurately. The first appearance of your concept becomes tangible and merchandisable.

Pilling test.

Pilling is a surface defect of textiles caused by wear, and is generally considered an undesirable trait. To measure the durability of our fabric, we put them to an intensive test module to analyze the strenght and ensure quality consistency. The results will be shared and published accordingly.

Rubbing test.

In the textile industry, a rub test determines the colorfastness of the color or dye in a fabric. It is an essential test. Fastness to rubbing also determines how well a fabric will resist stains. A test for fastness to rubbing can be performed on dry or wet fabric.

Colour fastness test.

If a fabric has good colorfastness, it is likely that it will resist fading when washed. Good marks on the rub test also indicate that a fabric is durable. Factors affecting the outcome of this test are how well the fabric is made, its color, its darkness, and how it will be used. Ensure your product quality standards are hitting the mark.